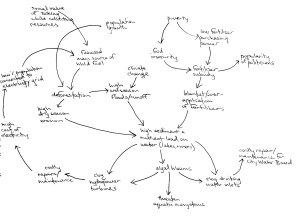

In land-locked Malawi, most phosphate fertilizers are imported from China and Morocco via the port at Mozambique. However, the country’s only fertilizer company, OPTICHEM, also manufactures fertilizers using local phosphate mined in Phalombe, a short distance from Blantyre, Malawi’s second largest city. Most of the food crops grown using these fertilizers are consumed in and around the City of Blantyre or for tobacco and tea exports. Malawi’s Ministry of Agriculture provides ambitious seed and fertilizer subsidies to farmers, most of whom are subsistence maize farmers. Deforestation and water pollution are two interrelated environmental challenges for the region, linked to energy demand, crop production and fertilizer use practices.

The P-FUTURES project aims to bring key local actors together, including peri-urban subsistence farmers, the wastewater service provider from Blantyre City Council, and the country’s primary fertilizer producer so that such challenges can be overcome. Food security, fertilizer access, improved sanitation and reversing environmental degradation are important drivers for the greater region of Blantyre.

Local research partner:

Center for Water, Sanitation, Health & Appropriate Technology Development (WASHTED), University of Malawi -The Polytechnic

Key contacts:

Dr. Bernard Thole bthole@poly.ac.mw & Save Kumwenda skumwenda@poly.ac.mw

Largely relying on imported phosphate via the port of Mozambique makes Blantyre vulnerable to disruptions and price fluctuations in the global phosphate market. The production of local fertilizers using renewable sources presents a great opportunity to increase farmer fertilizer security in Blantyre. The country’s only fertilizer company, OPTICHEM, with their production in the centre of Blantyre, have had recent success producing the country’s first commercial chicken manure fertilizer. OPTICHEM overcame the common odour challenges associated with manure use in urban areas by mixing the manure with local crop waste – tobacco husks.

Largely relying on imported phosphate via the port of Mozambique makes Blantyre vulnerable to disruptions and price fluctuations in the global phosphate market. The production of local fertilizers using renewable sources presents a great opportunity to increase farmer fertilizer security in Blantyre. The country’s only fertilizer company, OPTICHEM, with their production in the centre of Blantyre, have had recent success producing the country’s first commercial chicken manure fertilizer. OPTICHEM overcame the common odour challenges associated with manure use in urban areas by mixing the manure with local crop waste – tobacco husks.

The production manager and the company are proud of the success the product has had on the market, and are conceptually open to other organic feedstocks for fertilizer production. Quantities of organic feedstock continue to be a challenge for commercial production however. While there is a strong market demand for finished ‘renewable fertilizer’ products, the quantity and steady supply of organic feedstock – whether from manure or wastewater – is a limitation for commercial viability. As the production manager noted “don’t talk to me about 5 tonnes a day, come back when you have 100 tonnes a day”.